- Get link

- X

- Other Apps

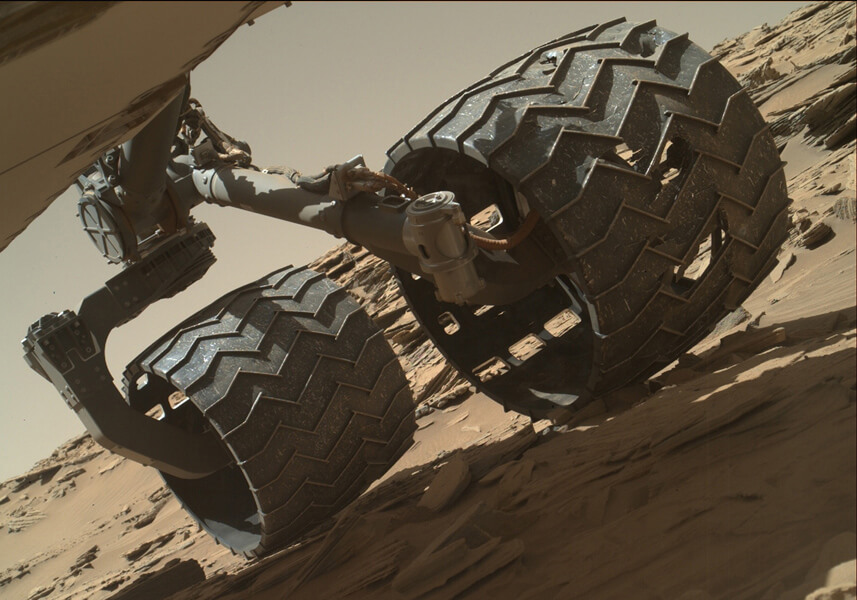

During his five-year stay on the Red Planet, the rover "Curiousity" has done a tremendous scientific work and has made many interesting scientific discoveries. And for all this time the autonomous Martian scientific laboratory, of course, had to travel a lot along the surface of our planetary neighbor. Nevertheless, in 2013, during a routine check, the management team of "Curiosity" was very surprised by the fact that all six wheels of the rover have various damages, including those shown in the image below.

Realizing that the future rover, which is going to be sent to the Red Planet by the mid-2020s, can expect similar problems, a team of engineers from the Glenn Research Center (NASA) decided to develop a new kind of wheels.

To begin with, perhaps it's worth it that the design of the new wheels is based on the earlier prototype Spring Tire - airless tires, developed by Goodyear in cooperation with NASA in the mid-2000s. Interestingly, the original version of such airless tires first appeared even earlier - in the bearded 70's and again as a result of the cooperation of Goodyear and NASA. However, in new tires, instead of using the spring-wire design used in the original models, the team from NASA decided to apply a more robust and flexible design.

The moon, Mars and other planets of the solar system have a very unfriendly, harsh landscape. In the case of the Moon, the main problem is the regolith covering the entire surface of the satellite. This shallow dust is a residual soil, which is the product of cosmic weathering of the rock and is capable of easily damaging the mechanical parts of the vehicle. On Mars, the situation can hardly be called simpler: there, most of the surface is covered not only with regolith, but also with small sharp stones that can easily cut even iron.

In 2013, after just one year of activity on the surface of Mars, the wheels of "Curiosity" began to show signs of serious wear and tear. This state of affairs made the scientists worried that they began to doubt that the rover could complete its planned mission. As a result, it also led to the fact that Glenn's research center decided to revise the design of tires, the development of which had already been underway for almost ten years. Tires were developed with the prospect of returning to the lunar program.

The development of new space tires for the Glenn Research Center in general was one of the priorities for the last ten years. In this regard, NASA engineers and scientists have returned several times to the developments that have been left since the era of the space missions "Apollo". At that time, as part of the development of the American and Soviet space program, several variants of tires designed for use on the lunar surface were developed. The Glenn Center chose three options as the basis.

The first was used in the Soviet "Lunokhod". In its eight-wheel base used metal tires, combined with the axis through a set of spokes. On the outer side of the tires there was a metal protector, designed to provide a more tight grip with the lunar soil.

The tires used in the special Modularized Equipment Transporter (MET), which was used by astronauts to transport lunar soil samples in one of the Apollo missions, also came under review. The development of tires for her was also carried out together with the company Goodyear. The car was unmotorized, and the astronauts had to apply considerable physical effort to transport it. Nevertheless, its tires had a smooth rubberized surface, which somewhat simplified its movement along the ground and stones.

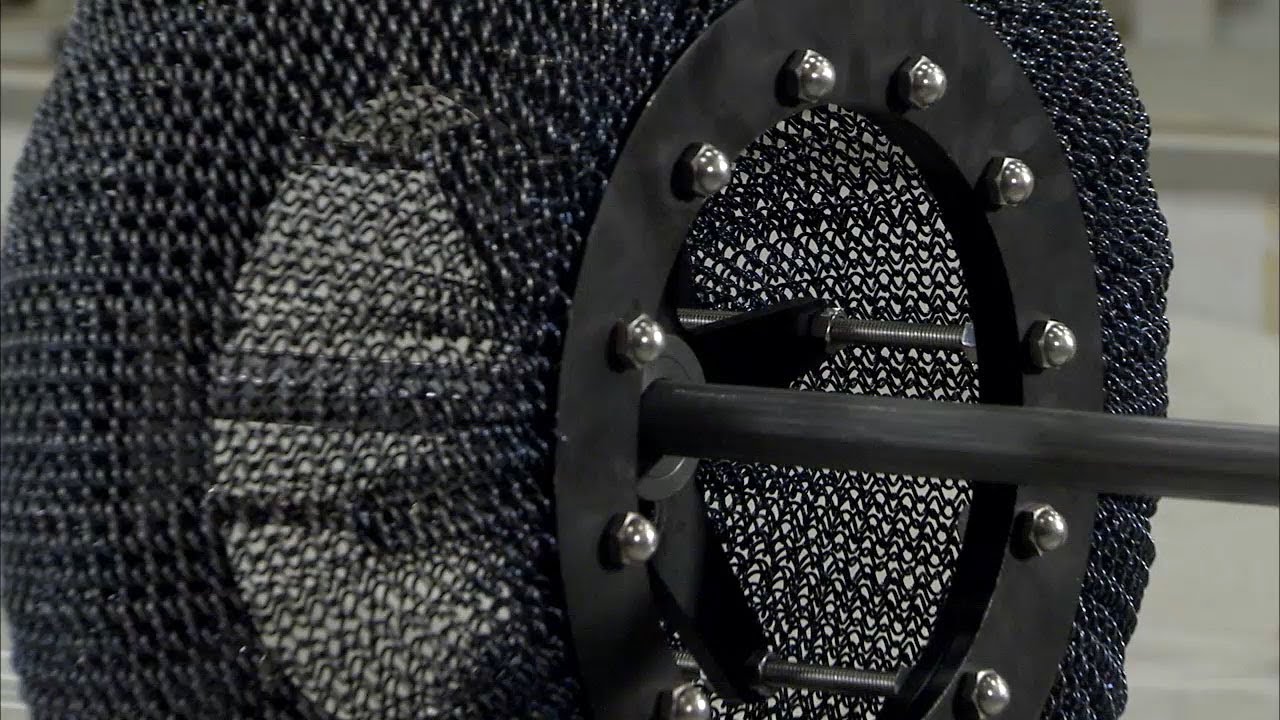

The third design of tires, which it was decided to address, was used in the so-called Lunar car, which was used by astronauts in the missions "Apollo-15", "Apollo-16" and "Apollo-17". This manned vehicle used four huge wheels with a strong inner frame and a tread in the form of a flexible wire mesh structure. In the mid-2000s, when NASA began to prepare for possible new lunar missions (with the prospect of future missions to Mars), the engineers decided to revise the design of the Lunar car tires, incorporating new technologies and using new and more durable materials. As a result, the light appeared the same tires Spring Tire. The tread of airless tires consisted of many interconnected metal rings (as in the chain mail), which made it both strong and flexible. This design not only allowed to reduce weight, but at the same time showed a high load capacity, even in conditions of movement over the severe surface.

To test the behavior of the Spring Tire tires on the surface of Mars, engineers from the Glenn Research Center began testing at a special test site designed to simulate surface conditions. In spite of the fact that in general the tires showed themselves worthily while moving along the simulated Martian soil, they faced a serious problem - the sharp stones on which the test sample moved started not only deforming the tires, but also literally breaking them.

As a result, the engineers again started to work. The solution was the use of super-elastic tires, which were the continuation of the "spring" tires of Spring Tire. The new tires use a special alloy of titanium nickelide, also known as nitinol. This material is the leader among alloys with shape memory effect. It is able to fully recover after 10 percent deformation. In the same tires Spring Tire, this figure is only 0.3-0.5 percent.

In addition, the advantage of tires from nitinol is low weight (in the same experimental prototype it is only nine kilograms), the ability to adjust the adhesion level to any surface and high damping properties. Tires with a memory effect are also increased and the index of flexibility, which generally should have a positive effect on their durability.

"Firstly, such tires will allow to carry out research on more diverse types of surfaces. Secondly, since they are lighter and in general able to adapt to a particular type of surface, they allow not to burrow into the ground, like harder and heavier wheels, and are able to cope with heavier loads. In addition, since form-memory buses are able to absorb energy from ground impact at different speeds, they can be used on controlled vehicles whose expected speed will be significantly higher than current rovers, "- noted on the Glenn Research Center website.

The use of superelastic tires need not be limited to the space program alone. Already, among the potential areas are considered tires for cars and SUVs, military, agricultural and aviation equipment. The developers have already installed an experimental tire on the Jeep Wrangler SUV and tested it in real conditions.

As for the first real use of such tires, this option will be available in the next few years, when NASA will send a new rover to the surface of the Red Planet. If everything goes according to plan, then it will take place somewhere in 2020. The new rover will be designed to replace "Curiosity" in its mission to find signs of life on Mars. In addition, the rover will be tasked with collecting samples of the Martian soil, which they plan to return to Earth as part of a manned mission, which will take place somewhere in the 2030s.

The article is based on materials .

- Get link

- X

- Other Apps

Comments

Post a Comment