- Get link

- X

- Other Apps

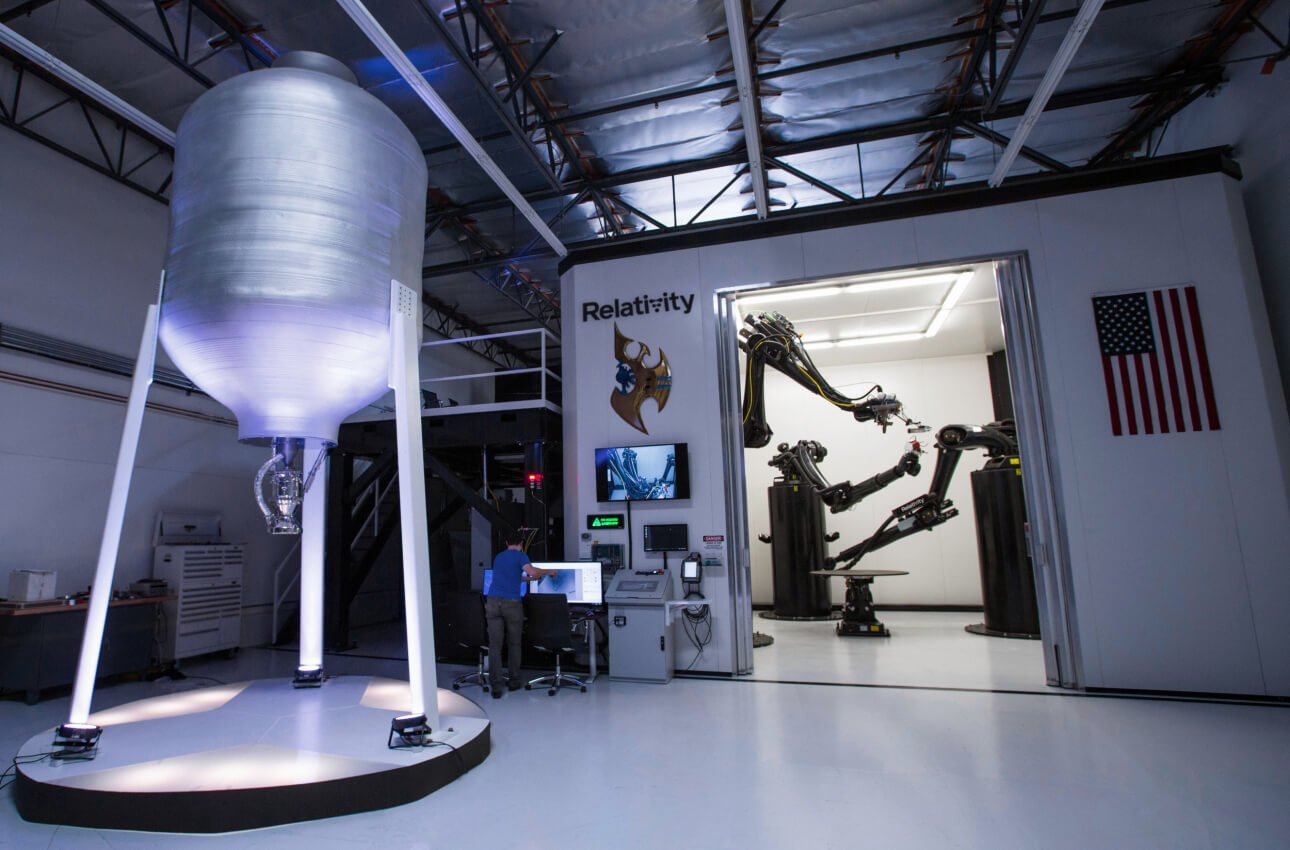

What can you do to make the production of space rockets ten times cheaper! Here, for example, the former employees of SpaceX and Bue Origin founded a startup Relativity Space, the purpose of which is to print missiles using 3D printers. According to the specialists of the newly minted company, this will help them to significantly reduce the price for the production and launch of the rocket.

The company's founders, Tim Ellis, who previously worked for Blue Origin, and Jordan Noon, a former SpaceX employee, believe that the use of 3D printers in the space field will soon be common, and the production of rockets using 3D printing is even more so, therefore, experts have combined in order to bring dreams closer to reality.

According to their plan, giant and fully robotic 3D printers will be involved in the creation of the missiles, which will print the entire rocket. The process of assembling another rocket is a tedious and difficult task, so why not entrust it to robots who can cope with a task as well as a human?

Six-meter robotic 3D printers can print a rocket engine in just a couple of weeks, and they only need a couple of days to produce a fuel tank. The whole process of rocket production will take from three to six months.

So far, the start-up doesn’t work without the help of people, therefore, in Relativity Space, they have tightened their belts and are working on the result. The company has only fourteen employees, who are already going to print the first rocket by 2020, and a year later, in 2021, already to launch it into space.

The article is based on materials .

- Get link

- X

- Other Apps

Comments

Post a Comment